| Rigid PCB | Flexible PCB | Rigid Flex PCB | |

|---|---|---|---|

| Layer | 1 ~ 32L | 1 ~ 6L | 16L; FCCL < 4L |

| Finished Board Thickness | 0.15~6.4mm | 0.05~0.3mm | 0.8~3.0mm |

| Max Panel Size | 0.15~A6.4mm | 500mm x 620mm | 500mm x 620mm |

| Inner layer Copper | Max 3 oz | Max 2 oz | Max 2 oz |

| Outer Layer Copper | Max 6 oz | Max 2 oz | Max 2 oz |

| Material | TG130 / TG150 / TG170 / TG180、Halogen Free、CTI 600、Roger / Isola、PTFE (Taconic)、Al (1W/mK, 2W/mK, 3W/mK) | Polymide | TG130 / TG150 / TG170 / TG180、Polymide |

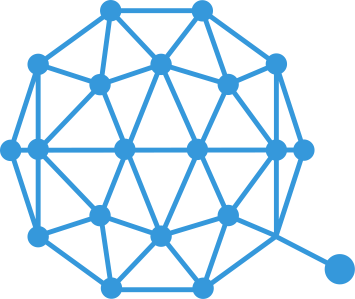

1.Track width and Clearance:

| Rigid PCB | Flexible PCB | Rigid Flex PCB | ||||

|---|---|---|---|---|---|---|

| Min | Typ | Min | Typ | Min | Typ | |

| Track width (mil/mm) | 3/0.075 | 4/0.10 | 3/0.075 | 4/0.10 | 3/0.075 | 4/0.10 |

| Tolerance of Track width | 10% | 20% | 10% | 20% | 10% | 20% |

| D0 (mil/mm) | 4/0.10 | 6/0.15 | 4/0.10 | 6/0.15 | 4/0.10 | 6/0.15 |

| D1 (mil/mm) | 3/0.075 | 4/0.10 | 3/0.075 | 4/0.10 | 3/0.075 | 4/0.10 |

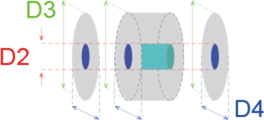

2.Via dimension (Mechanical) & Pad dimension:

| 2A.Via dimension | Rigid PCB | Flexible PCB | Rigid Flex PCB | ||||

|---|---|---|---|---|---|---|---|

| Min | Typ | Min | Typ | Min | Typ | ||

| D2 (mil/mm) | 8/0.20 | 12/0.30 | 8/0.20 | 12/0.30 | 8/0.20 | 12/0.30 | |

| D3 (mil/mm) | 16/0.40 | 20/0.50 | 16/0.40 | 20/0.50 | 16/0.40 | 20/0.50 | |

| D4 (mil/mm) | 16/0.40 | 20/0.50 | 16/0.40 | 20/0.50 | 16/0.40 | 20/0.50 | |

| Size tolerance (mil/mm) | PTH hole | 3/0.075 | 3/0.075 | 3/0.075 | 3/0.075 | 3/0.075 | 3/0.075 |

| NPTH hole | 2/0.05 | 2/0.05 | 2/0.05 | 2/0.05 | 2/0.05 | 2/0.05 | |

| Plating thickness in hole (mil/mm) | Avg | Typ | Avg | Typ | |||

| 0.8/0.020 | 1.0/0.0254 | 0.8/0.020 | 1.0/0.0254 | ||||

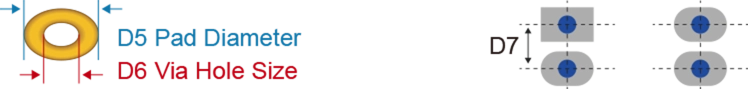

| 2B. Pad dimension | Rigid PCB | Flexible PCB | Rigid Flex PCB | |||

|---|---|---|---|---|---|---|

| Min | Typ | Min | Typ | Min | Typ | |

| D5 (mil/mm) | 16/0.4 | 20/0.5 | 16/0.4 | 20/0.5 | 16/0.4 | 20/0.5 |

| D6 (mil/mm) | 8/0.2 | 12/0.3 | 8/0.2 | 12/0.3 | 8/0.2 | 12/0.3 |

| D7 (mil/mm) | 20/0.5 | 28/0.7 | 20/0.5 | 28/0.7 | 20/0.5 | 28/0.7 |

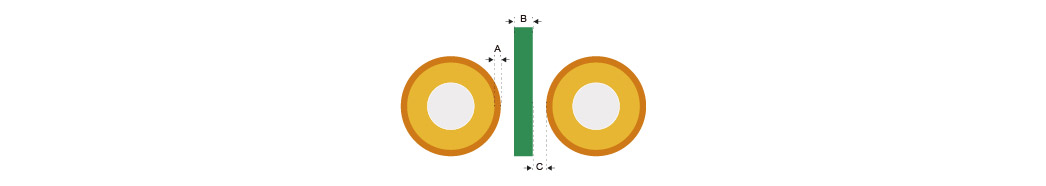

3. Soldermask:

| Flash gold board (bonding PCB) | Immersion gold board | Gold finger board | ||||

|---|---|---|---|---|---|---|

| Min | Typ | Min | Typ | Min | Typ | |

| A Soldermask Opening |

2/0.05 | 4/0.10 | 2/0.05 (Coverlay 4/0.1) | 4/0.10 | 2/0.05 | 4/0.10 |

| B Soldermask Dam |

4/0.1 *Possible Peeloff |

8/0.2 | 4/0.1 *Possible Peeloff (Coverlay 8/0.2) |

8/0.2 | 4/0.1 *Possible Peeloff |

8/0.2 |

| C Pad to Trace Spacing |

4/0.1 *Caution on Solder Short |

8/0.2 | 4/0.1 *Caution on Solder Short |

8/0.2 | 4/0.1 *Caution on Solder Short |

8/0.2 |

4. Gold thickness and Nickel thickness:

| Flash gold board (bonding PCB) | Immersion gold board | Gold finger board | ||||

|---|---|---|---|---|---|---|

| Min | Typ | Min | Typ | Min | Typ | |

| Gold thickness ( u" / um ) |

1/0.025 | 4/0.10 | 2/0.05 | 4/0.10 | 1/0.025 | 50/1.27 |

| Nickel thickness ( u" / um ) |

120/3 | 400/10 | 120/3 | 400/10 | 120/3 | 400/10 |

5. Solder resist color

| Soldermask | Green | Blue | White | Black | Red | Yellow |

| Coverlay | Yellow | White | Black | |||

6. Surface Finishing

| ENIG | LF HASL | OSP | Immersion Silver |

| Immersion Tin | Pb HASL | Gold Plating | ENEPIG |

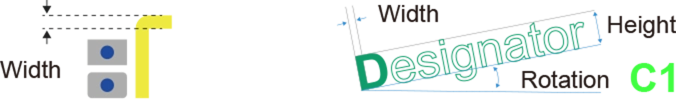

7.Silk screen

| Dimension | Min | Typ |

|---|---|---|

| Outline width (mil/mm) | 4/0.10 | 5/0.13 |

| Designator width (mil/mm) | 4/0.10 | 5/0.13 |

| Designator height (mil/mm) | 31/0.80 | 60/1.50 |

| Clearance of near two designators (mil/mm) | 4/0.10 | 6/0.15 |

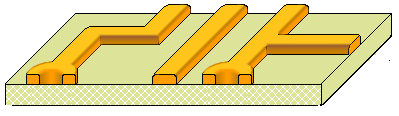

8. Hole Handling

| No cover | Soldermask Tending | Soldermask Plugging | Resin Plugging | VIPPO |

9.Outline Tolerance

| Technology | Min | Typ |

|---|---|---|

| Router | +/-0.05 | +/-0.1 |

| V-cut | +/-0.3 | +/-0.5 |

| Punching Tool (1 to 4L only) | +/-0.05 | +/-0.1 |

| Laser (FPC) | +/-0.05 | +/-0.1 |

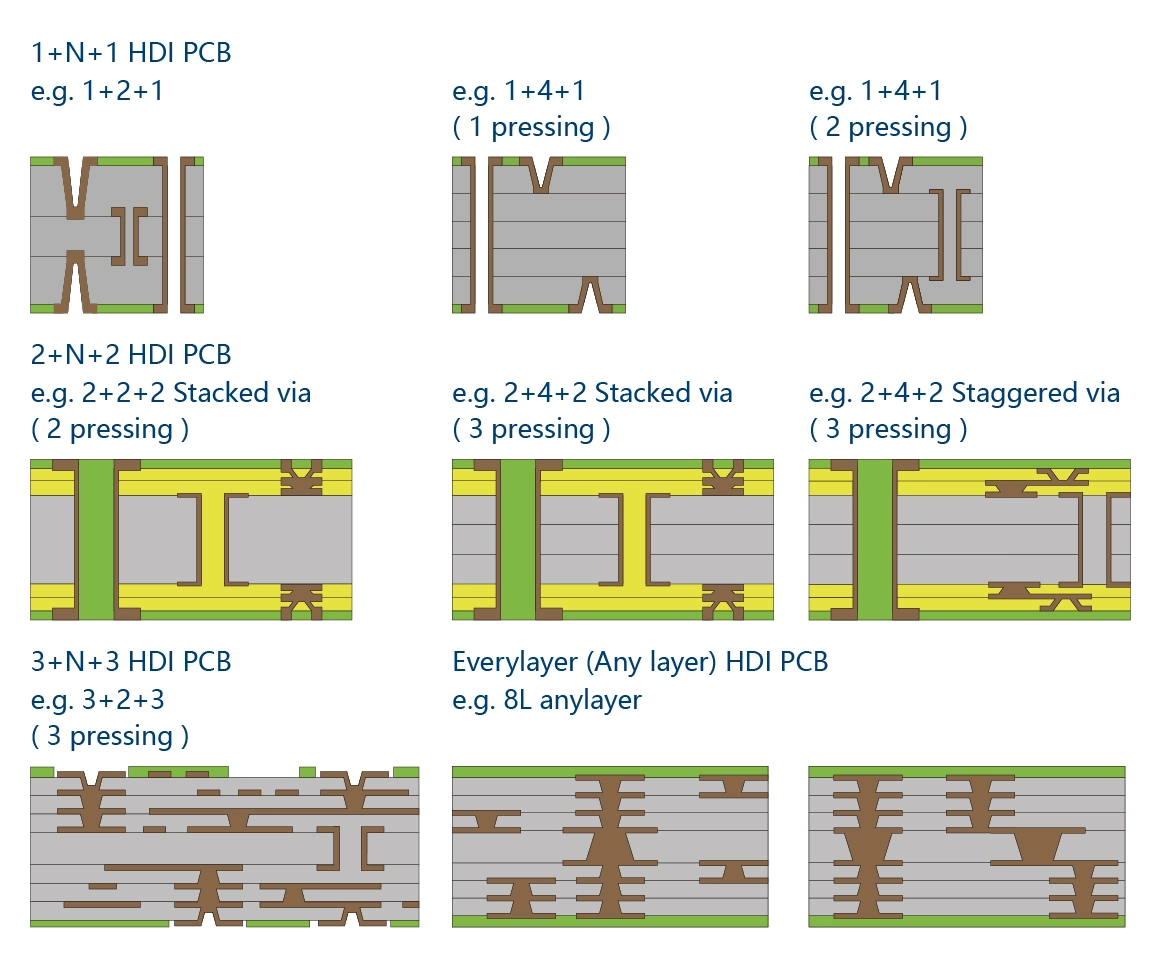

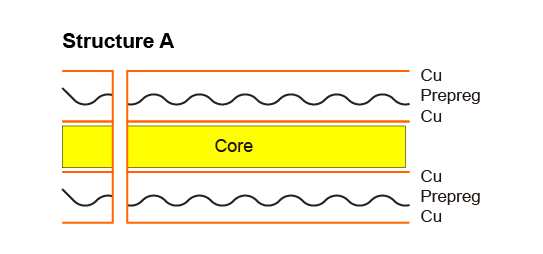

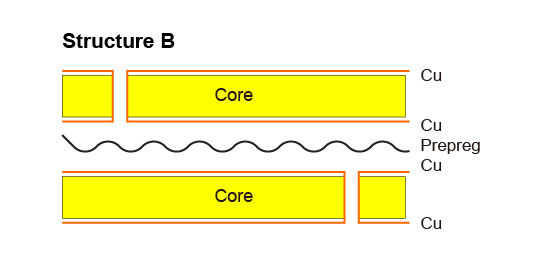

| Structure | Specification | Structure | Specification | ||

|---|---|---|---|---|---|

|

Min Cu thickness (final) | H/H/H/H oz |  |

Min Cu thickness (final) | H/H/H/H oz |

| Min Board thickness | 0.4mm +/-0.1mm | Min Board thickness | 0.4mm +/-0.1mm | ||

| Min hole size (PTH) final | 0.2mm | Min hole size (PTH) final | 0.2mm | ||

| Min hole size (NPTH) final | 0.3mm | Min hole size (NPTH) final | 0.3mm | ||

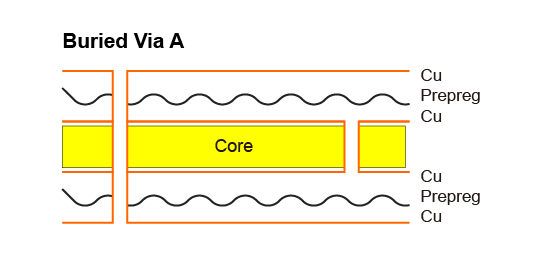

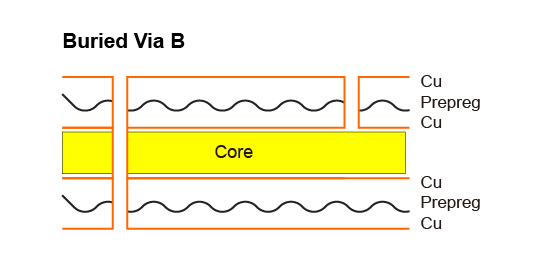

| Buried Via | Specification | Blind Via | Specification | ||

|---|---|---|---|---|---|

|

Min Cu thickness (final) | H/H/H/H oz |  |

Min Cu thickness (final) | H/H/H/H oz |

| Buried via size | 0.1mm | Blind via size | 0.1mm | ||

| Min via in pad | 0.15mm | ||||